Parts of Cantilever Gate Systems

Cantilever gates are unique from other gates because they don't roll on the ground, instead operating using rollers positioned at the top and bottom of the frame and moving in a sliding fashion. When installing a cantilever gate, it's important to ensure your installation surface area is level because if there is any gradient, it will affect the cantilever gate's ability to slide smoothly and to stay open or closed. With a cantilever gate that has an opening of 27' or less, a single-track setup can be used, while a double-track setup is the best fit for gates larger than 27' or decorative gates that feature solid or semi-solid fill. In such setups, one track is placed on each side of the gate at both the top and bottom. Understanding the necessary components is crucial to installing a sliding gate at any commercial or industrial site. Incorrect installation of a cantilever gate can lead to faulty operation, which can compromise safety and security. We've put together this guide to help you and your business better understand a sliding cantilever gate system, so you can feel confident in your installation or maintenance.

Why Should You Use a Cantilever Gate System?

High Performance in Demanding Environments

Cantilever gates glide without contacting the ground, eliminating weather-related obstructions like snow, gravel, or mud that often jam traditional track systems. They deliver consistent, reliable access even on uneven terrain, which is ideal for busy industrial yards and high traffic entry points.

Lower Operational and Maintenance Costs

Because there's no ground track to clear or repair, these systems require minimal upkeep. Reduced wear on rollers and fewer moving parts translate into fewer service calls and lower lifetime costs, making them a cost-effective option for facilities where uptime and budget control matter.

Quiet, Smooth, and Predictable Operation

Supported by precision rollers and counterbalance mechanisms, these systems run quietly and without friction with the ground. This results in smooth, consistent cycling, which is beneficial for professional facilities where noise, dust, or operational hiccups are unacceptable.

For businesses managing secure perimeters, high-traffic vehicle access, or facilities in harsh or debris-prone environments, a cantilever gate system offers unmatched reliability, simplified maintenance, and flexibility in design and automation; a strategic investment in functional security infrastructure that pays dividends over the long haul.

A Guide to Cantilever Gate systems and their Parts

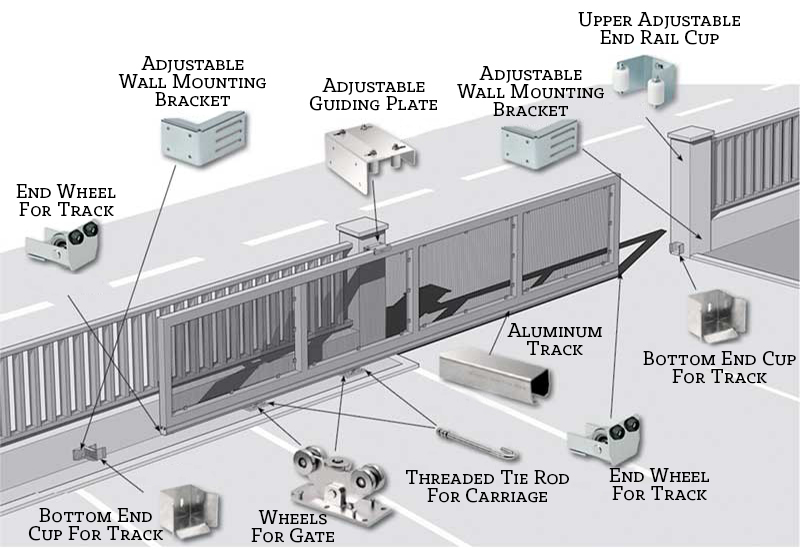

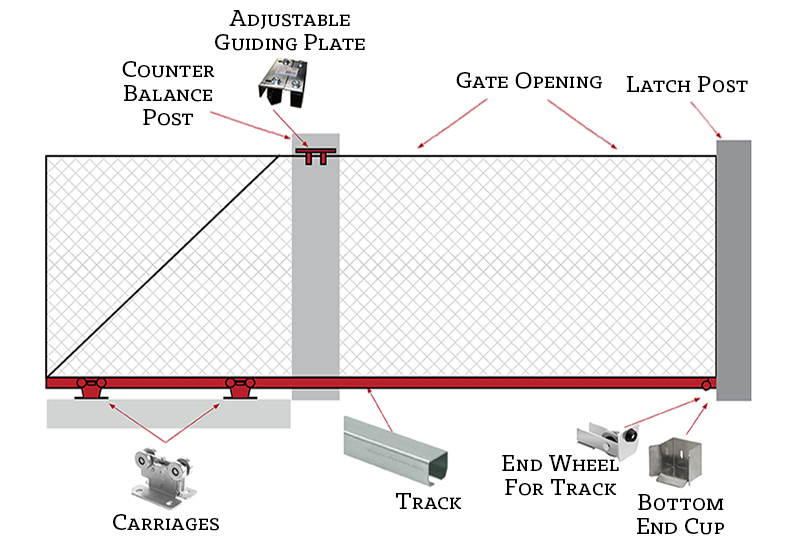

Parts Featured In The Diagram

Adjustable Wall Mounting Brackets:

Adjustable wall mounting brackets are used to secure components (such as end cups) of a cantilever gate to an existing wall or structural surface.Carriages:

A carriage (also called a roller assembly or truck assembly) is a steel or aluminum housing that contains a set of high-load-bearing wheels or rollers. They bear all the weight that the gate has, and are necessary to allow the gate to slide.End Cups:

End Rail Cups accept and hold the end of a cantilever gate, keeping it fixed in place as the gate is closed.End Wheel:

An end wheel is a small, non-load-bearing wheel mounted on the leading edge of a cantilever gate. As the gate slides close, the end wheel makes light contact with the ground or a ground track, helping to guide the nose of the gate into position and stabilize it during closure.J-Bolt Threaded Tie Rod:

A threaded tie rod is a load-bearing steel rod used to reinforce the structural frame of the gate. It plays a critical role in maintaining the integrity, alignment, and stability of the gate frame.Guiding Plates:

Guiding Plates help ensure that a cantilever gate remains on the proper path as it opens and closes. They're fitted with rollers and make contact with the gate frame, usually along the top rail or sometimes both top and bottom.Tracks:

In a cantilever gate system, the track is a steel channel welded to the bottom (and sometimes top) of the gate frame. It serves as the pathway that rides over the carriage rollers, allowing the gate to float and glide across the opening without ever touching the ground. They are designed with a C-shape whose opening is positioned on the side where the gate will pass.Additonal Parts Not Featured In The Diagram

Cantilever Hinges:

Cantilever gate hinges are specialized mounting brackets that allow the gate frame to pivot or connect to a fixed structure in non-sliding or hybrid installations, typically used when traditional posts aren't available or when modular adjustment is needed.Roller Guides:

Roller guides (or guide rollers) are hardware components that live inside or alongside guide plates/brackets mounted at the gate's receiving post or along the path of travel. They consist of rollers that are mounted in steel brackets, which interface with the gate frame as it slides.Tension Bars:

A tension bar is a stainless steel turnbuckle-style adjustment mechanism installed at the tail end of a cantilever gate. It fits into square tubing and provides minor vertical adjustment when a cantilever gate loses tension and begins to sag.U-Channel Guide Rails:

A U-channel guide rail (often called a guide rail or guide channel) is a rigid, U-shaped steel or aluminum track welded to the rear of a cantilever gate frame. It engages with side-mounted guide rollers to stabilize the gate, helping prevent lateral sway and ensuring the gate slides smoothly and remains aligned throughout its travel.Understanding the anatomy of a cantilever gate system is essential to getting the performance, longevity, and reliability your site demands. Each component plays a specific role in ensuring your gate operates smoothly and securely. Whether you're planning a new install or troubleshooting an existing system, selecting the right parts is critical, and even small mismatches can lead to costly downtime or operational issues. If you're unsure which hardware best fits your application or needs help navigating options, our expert sales team is here to help. Don't hesitate to give us a call! We'll walk you through it and make sure you get exactly what you need the first time.

Contact Us