Cantilever Gate Hardware 101

Cantilever gates are a trusted standard in commercial and industrial perimeter security, offering reliable, low-maintenance access control in high-traffic and heavy-duty environments. Unlike traditional swing or tracked sliding gates, cantilever systems operate without in-ground tracks, "floating" the gate across the opening by way of a counterbalanced design and internal rollers. This makes them ideal for uneven terrain, snow-prone regions, and applications where ground debris or grading poses a challenge.

Understanding the hardware behind a cantilever gate is essential for anyone involved in specifying, installing, or maintaining gate systems. Each component, from the structural support posts to the internal roller carriages, plays a key role in functionality, durability, and safety. This article provides a breakdown of the core hardware used in cantilever gate systems, including what each part does, where it fits into the system, and why proper selection and installation matter.

Overview of Cantilever Gate Systems

At a high level, a cantilever gate system is designed to provide smooth lateral movement across a gated opening without the use of in-ground tracks. This is achieved through a carefully engineered counterbalance system that suspends the gate between roller carriages mounted to support posts. As a result, the gate glides above the surface, making it highly effective in areas where dirt, snow, ice, or uneven pavement would compromise traditional track-based or swing gate systems.

Primary Use Cases

- Commercial & Industrial Sites: Warehouses, distribution yards, airports, and utility compounds where high cycle rates, wide openings, and minimal maintenance are priorities.

- Municipal & Institutional Settings: Schools, public works, and government facilities that require secure access points with durable hardware.

- Residential Applications (Selective Use): In higher-end or space-constrained residential installations, cantilever systems are sometimes used, especially where traditional swing gates are impractical due to grading or obstacles.

Basic Components

The basic core components of cantilever gates include wheel carriages, guiding plates, and a track. The gate itself is supported by the weight-bearing roller carriages that contain internal wheels which the gate itself rolls across, creating the ‘floating' motion. To keep the gate in line as it moves, an U-shaped track is used, keeping the gate system stable and secure. Additional stability is provided with guiding wheel plates, provides an added wheel system to support the gate as it opens and closes. These are the basics, but there is still a lot more hardware that goes into a cantilever gate system.

Understanding how these systems are laid out helps clarify where each hardware component fits. The following sections will break down the major structural elements and moving parts that make cantilever gates function reliably.

Carriages

Roller carriages, also known as roller trucks, are the foundation of cantilever gate performance. These components bear the full weight of the gate, enabling it to glide smoothly over the opening without contact with the ground. Properly specified and installed carriages are essential to:

- Ensure stable, low-friction movement under heavy-duty usage.

- Maintain long-term structural alignment, reducing wear on gate motors and components.

- Provide reliable operation in harsh conditions-from industrial yards to snow-laden or uneven driveways.

Carriages come in several configurations to match different gate sizes, weight capacities, and environmental conditions. The most common variations include differences in wheel count, material composition, and overall load rating, which are each designed to meet specific performance demands.

- 5-Wheel Carriages (Nylon or Steel): Best suited for lighter-duty or residential gates, these provide efficient load-bearing with a compact footprint.

- 8-Wheel Carriages: Engineered for heavier gate applications, these distribute weight across more points and offer improved stability and durability.

- 9-Wheel Carriages: Designed for industrial/commercial environments, these robust units support gates weighing several thousand pounds or exceeding 50 feet in width.

- Adjustable 18 Wheel Mono Carriage: This compact mono carriage combines a high wheel count with an adjustable body, making it ideal for tight clearances or custom applications where precision fit and stable tracking are critical.

Tracks

A cantilever gate track refers to the internal guide system built into the bottom or top of a cantilever gate frame. Unlike traditional sliding gates that rely on ground-level tracks, cantilever tracks support the gate through an embedded channel, allowing rollers to ride inside the structure, enabling the gate to "float" without touching the ground. This enclosed setup makes the system more reliable, especially in commercial or industrial environments where debris or weather can impact ground-level rails. Tracks are essential to:

- Guide and support the gate through sealed bearings, ensuring smooth, low-friction operation and less wear over time.

- Eliminate ground contact, avoiding issues like ice, snow, gravel, or dirt buildup that can jam or damage ground-based tracks.

- Enhance structural integrity, maintaining alignment and reducing stress on rollers or gate motors.

Types of Cantilever Gate Tracks

- Galvanized Steel Tracks: Durable and corrosion-resistant, ideal for heavy commercial or industrial gates. Works well in demanding environments.

- Aluminum Tracks: Lightweight with good strength-to-weight ratio, these tracks reduce load and facilitate easier installation-well-suited for moderate-duty installations.

- Stainless Steel Tracks: Highly corrosion-resistant and low maintenance, perfect for coastal or harsh chemical environments.

- Weld-In vs. Bolt-On Designs: Internal tracks may be welded into the gate frame for a seamless and robust setup or offered as bolt-on extrusions-more modular and easier to replace or retrofit.

Guiding Plates

Guiding plates are top-mounted guide assemblies affixed to cantilever gate posts (or frame edges) designed to keep the gate aligned and prevent lateral sway during movement. Unlike load-bearing rollers, these components manage side-to-side stability, particularly under wind pressure or in gates with heavy infill. Guiding plates are essential for:

- Vertical Stabilization: They steady the gate as it travels, ensuring clean, smooth, and safe operation.

- Safety Compliance: By minimizing wobble and reducing pinch or shear zones, guiding plates help meet UL 325 and ASTM F2200 standards.

- Adaptable Performance: Particularly useful for gates with solid panels, privacy slats, or in windy environments where sway risks are elevated.

Types of Guiding Plates:

- For 2 3/8" Gate Frames: Compact guiding plates with smaller roller spacing-ideal for light-duty or residential applications. Provides clean tracking with minimal resistance.

- For 3 1/8" Gate Frames: A step up in capacity, this size supports mid-weight commercial gates with moderate exposure to wind or uneven infill. Often used in storage facilities, small lots, or distribution centers.

- For 4 3/8" Gate Frames: Designed for larger, heavier-duty gates that require enhanced lateral stability. Common in industrial yards, municipal access points, or solid panel gate systems.

- For 4 3/4" Gate Frames: The largest standard offering optimized for wide-span gates or systems operating in extreme conditions (e.g., coastal wind zones or high-cycle freight entrances). Reinforced construction provides excellent control without compromising glide performance.

J-Bolt Threaded Tie Rod

Threaded J Bolt Tie Rods serve as the primary anchoring interface between cantilever gate carriages and their supporting concrete foundation. Shaped like a "J" the curved bottom portion embeds into the concrete pad during the pour. The straight, threaded upper portion protrudes for mounting gate hardware, providing a durable, stable anchor that resists both tensile stress and vibration. The key roles of the J-Bolt is to:

- Anchor trolley carriage assemblies securely to the foundation.

- Enable fine-level adjustment and precise alignment particularly when used with foundation plates or grout support.

- Maintain long-term positional stability under repeated gate cycles and heavy commercial/industrial use cases.

Types of J-Bolts

- For Gates Up to 700 lbs: Light-duty J-bolts are suited for larger residential gates or smaller commercial gates. These anchors are simple to install and provide adequate support for 5-wheel carriages used in gates under 26 feet wide.

- For Gates Up to 1,700 lbs: Larger threaded J-bolts are a mid-range option commonly used in heavier commercial applications or light industrial applications. Ideal for medium-sized cantilever systems, these rods provide reliable anchoring for gates up to 26 feet wide.

- For Gates Up to 4,050 lbs: Heavy-Duty threaded J-bolts are anchors built for large industrial systems. Designed for wide-span gates up to 59 feet, these rods are compatible with high-capacity carriages, offering long-term durability under heavy loads and high-cycle use.

End Wheel

End wheels are roller assemblies located at the trailing end of a cantilever gate. They serve to support the gate when it's fully extended-reducing frame stress, maintaining proper alignment, and preventing sag or bind at the end of the run. Unlike primary rollers or carriages, end wheels deal with end-of-travel support rather than full load-bearing. The key role of the end wheels is to:

- Prevent Frame Sag: When the gate is fully opened, the rear portion can dip over time. The end wheel acts as a brace, reducing cantilevered stress on the frame and welds.

- Improve Glide Stability: By keeping the rear section aligned and supported, end wheels reduce lateral movement and help the gate retract smoothly without vibration or wobble.

- Extend Hardware Life: Supporting the gate tail helps protect the internal roller carriages from carrying the full gate weight over long distances-especially important in heavy-duty, wide-span installations.

- Reduce Maintenance: Reduces misalignment issues over time, helping maintain clean tracking and lower service frequency.

Types of End Wheels Based on Capacity

- For Medium Systems: Designed for gates up to approximately 26 feet wide and 1,700 lbs in weight. These end wheels are commonly used with mid-size commercial installations, offering compact support without adding bulk.

- For Large Systems: Built for larger cantilever gates up to 65 feet wide and 7,700 lbs. Heavy-duty construction ensures long-term durability under frequent cycles and high tail-end stress.

End Cup

End cups are track-receiving assemblies fixed to the concrete foundation or ground surface. They securely cradle the cantilever gate's end track when the gate is fully open or closed. Typically constructed from aluminum, galvanized steel, or stainless steel, end cups feature a flared or beveled leading edge to smoothly guide the track into place, while minimizing vibration and wear. End cups are essential because they:

- Provide Structural Support at End Position: They steady the gate at full travel, preventing misalignment and reducing frame stress.

- Absorb Vibration: By cushioning the gate's endpoint, end cups protect internal rollers and the drive mechanism from impact.

- Promote Smooth Engagement: Their beveled entry design helps the track glide in silently and efficiently-critical in high-cycle or industrial environments.

Types of End Cups

- Bottom End Cup for Small Frames (550-700 lbs): Compact aluminum design ideal for light-duty or residential gates. Ensures smooth track engagement and basic support.

- Bottom End Cup for Medium Frames (900-1700 lbs): Steel-bodied end cups for mid-weight commercial installations, offering enhanced durability for frequent use.

- Bottom End Cup for Heavy Frames (4050-7700 lbs): These heavy-duty variants are built for extra-large commercial gate systems. Offers reinforced support for wide spans and mass loads.

- Upper Adjustable End Cups (Small, Medium, Large): Bolt-on adjustable receivers with roller assistance have the capability of customizing the size of gate frame that it can take, providing versatility for a range of applications.

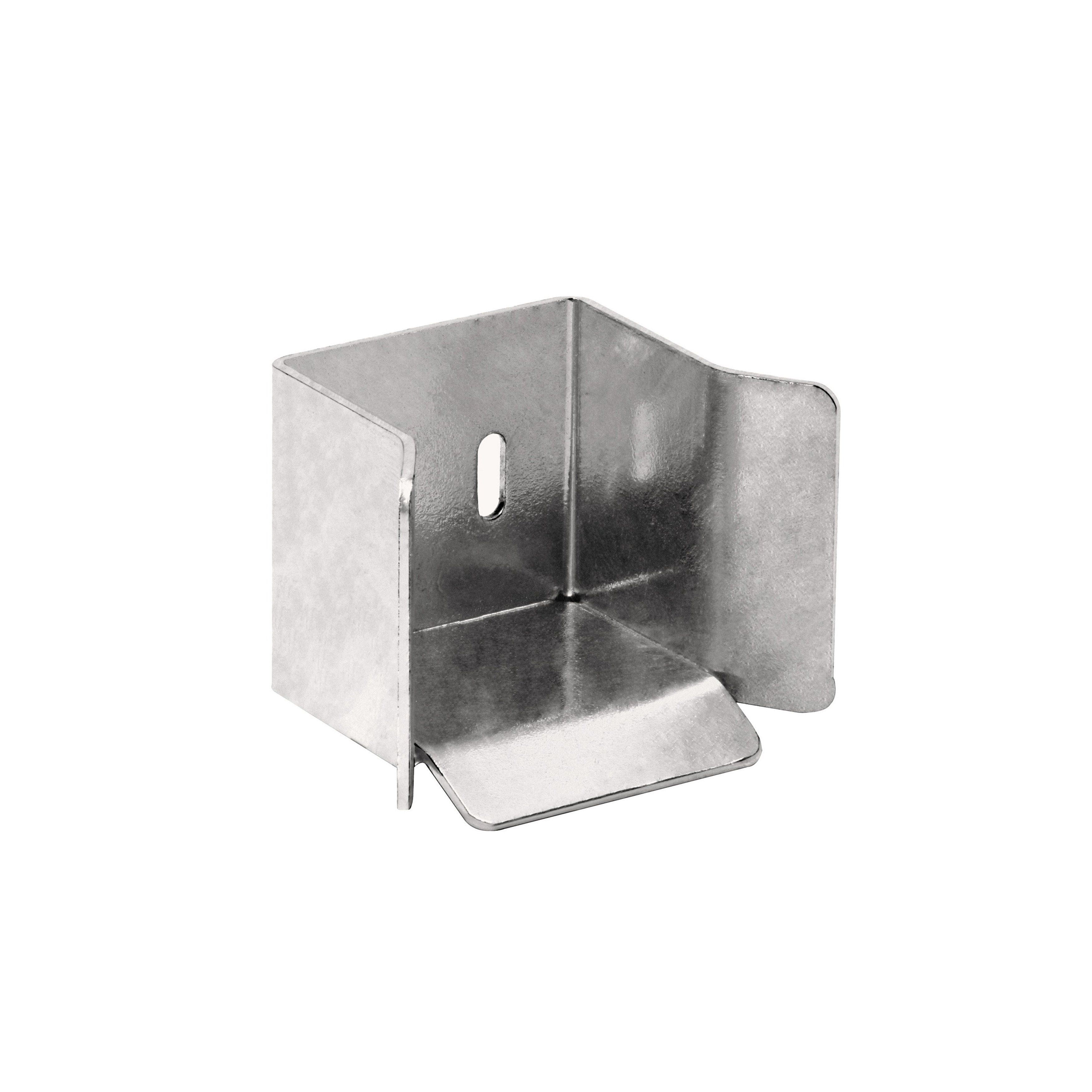

Adjustable Wall Mounting Brackets

Adjustable wall mounting brackets are structural support components used to secure end cups to a wall, column, or fixed structure. These brackets offer horizontal and vertical adjustment slots, enabling precise alignment of the gate's end position. These end cups are necessary because they:

- Enable Non-Ground Mounting: Provide a strong anchor point for end receivers or cups when a concrete pad isn't available.

- Allow for Precision Alignment: The slotted design allows the installer to fine-tune the bracket's position during installation, ensuring the gate enters the receiver smoothly and evenly.

- Support Structural Load at End of Travel: Especially in longer or heavier gates, proper end support is critical to maintaining gate alignment and relieving pressure on carriages and track.

Types of Adjustable Wall Brackets:

- 6 1/2" x 4 5/16" Bracket: Used for light-duty cantilever gates up to 900 lbs and 13 ft in length. Ideal for residential or smaller commercial applications where end cups need to be mounted to a wall instead.

- 7 1/2" x 4 5/16" Bracket: Designed for mid-weight gates up to 1,700 lbs and 26 ft long. Common in commercial installations, this size offers added strength while still fitting tight mounting areas.

- 8 11/16" x 4 3/4" Bracket: Built for heavy-duty systems supporting gates up to 4,050 lbs and 59 ft wide. This is the largest and most robust bracket, used in industrial or high-cycle environments where structural reinforcement is essential.

U-Channel Guide Rails

U Channel Guides are upper guide rails that are shaped like a "U" and are used as additional support to align cantilever gates. Positioned along the gate's upper edge, they interact with side-mounted guide rollers to maintain vertical alignment while keeping the top hardware discreet and out of sight. U-Channels' key roles include:

- Maintain Gate Alignment: Prevents sway, drift, or derailment by providing consistent lateral support along the gate's top edge.

- Enable Hidden Guiding: Ideal when top rails or ornaments would interfere with traditional guide rollers; the channel conceals the guiding mechanism.

- Prevents Gate Lift and Gate Rattle During Operation: U channel guides help contain vertical movement by cradling the edge of the gate inside the channel. This prevents the gate from lifting or vibrating when in motion.

Types of U-Channel Guides

- Standard Cantilever Gate U Channel: Designed for single-panel cantilever gates. These are most often used in commercial and decorative gate systems where the gate has an arched or non-linear top rail. The U channel keeps the gate vertically aligned without needing exposed top rollers, preserving both appearance and function.

- Ranger Telescoping Gate U Channel: Specially engineered for multi-panel telescoping systems, such as the Ranger series. These channels are used to guide the lead panel while allowing nested panels to retract independently. Their role is crucial for keeping multiple moving leaf sections aligned, especially over longer spans and during fast operation cycles.

Cantilever Hinges

Cantilever gate hinges are used in bi-folding gate systems and are specialized pivot hinges that allow two or more connected gate panels to fold in on themselves during opening or closing. These hinges are mounted between gate leaves and posts, enabling inward or outward folding action while maintaining precise alignment and consistent movement throughout the gate cycle. Key roles of cantilever hinges:

- Enable Folding Motion in Limited Space: These hinges allow gate panels to pivot and fold instead of sliding fully to one side, making them ideal for confined areas, tight entrances, or sites with limited run-back distance.

- Maintain Structural Alignment Under Motion: Bi-folding hinges absorb the rotational force between panels while keeping the assembly secure, stable, and aligned especially under repetitive movement or automated operation.

- Support High-Traffic Applications: Heavy-duty variants are designed to withstand the wear of frequent use, making them suitable for commercial, municipal, or gated community entries that cycle multiple times per day.

Types of hinges

- Weld-On Pivot Hinges: Provide permanent, high-strength connections between folding panels. Ideal for long-term installations where structural rigidity is a priority.

- Bolt-On Adjustable Hinges: Allow for on-site adjustment during installation, making them more flexible for custom gate configurations or projects with variable panel sizes.

Tension Bars

Tension bars function like an integrated turnbuckle within the cantilever gate framework. Typically made of stainless steel, they insert into the gate's tubing and allow minor vertical adjustments and are especially useful for compensating gate sag or post settlement over time. Why they matter:

- Compensate for Gate Sag and Settlement: Over time, heavy or long gates may sag or shift due to gravity or foundation settling. The tension bar affords an accessible adjustment method, restoring alignment without dismantling the gate.

- Align Double-Gate Leaves Precisely: In double or bi-parting cantilever systems, ensuring both gate leaves meet perfectly at the center is critical. The tension bar simplifies this alignment, improving sealing and enhancing operational smoothness.

- Maintain Long-Term Operational Integrity: By providing intermittent adjustability as conditions change, tension bars reduce stress on roller carriages and tracks, prolonging service life and decreasing maintenance costs.

Key features

- Stainless steel construction: Corrosion-resistant for durability in industrial and outdoor environments.

- Broad compatibility: Fits common tubing profiles.

Quick-Reference: Cantilever Gate Components at a Glance

To simplify selection and assist with fast hardware identification, we've included a quick-reference table outlining the most common cantilever gate components, what they do, and where they're typically used. Whether you're assembling a full system or troubleshooting an existing one, this table provides a clear summary of each part's function and purpose. Ideal for installers, specifiers, and procurement teams needing a fast lookup.

| Hardware | Purpose | |

|---|---|---|

|

Carriage | Supports weight of the gate and utilizes wheels for sliding operation |

|

Tracks | Guide system that supports the carriages and keeps gate in line |

|

Guiding Plate | Top mounted rolling guide that keeps the gate aligned |

|

J-Bolt | Primary anchoring interface between carriages and the concrete |

|

End-Wheel | Wheeled braces the tailing end of the gate when fully closed to ensure stability |

|

End Cup | Receives the track when the gate is fully open or fully closed |

|

Adjustable Wall Brackets | Structural support used to secure end cups to a fixed structure |

|

U-Channel Rail Guide | Additional support mounted at gate's upper edge to maintain alignment |

|

Cantilever Hinges | Specialized bi-folding gate hinges to enable folding action |

|

Tension Bar | Allows for minor vertical adjustments to prevent gate sag |

Cantilever gate systems are only as reliable as the hardware behind them. From carriages and tracks to end cups, hinges, and adjustment components, each part plays a vital role in ensuring smooth operation, structural integrity, and long-term durability. Whether you're designing a new system or retrofitting an existing one, understanding how these components work together is key to building a gate that performs as expected in any environment. If you're unsure which parts are right for your application, or simply want help navigating all the options, don't hesitate to call our expert sales team. We're here to help you choose the right hardware for the job!

Contact Us